Cutting-edge Tools and Techniques for Accurate Gauge Fillet Weld Measurements

Cutting-edge Tools and Techniques for Accurate Gauge Fillet Weld Measurements

Blog Article

Cutting-edge Strategies to Fillet Weld Assessment and Testing: Enhancing Weld Quality and Conformity Requirements

In the world of welding, the quality and integrity of fillet welds play an important role in guaranteeing the architectural stability and integrity of different industrial elements. With the continuous drive for boosted effectiveness and compliance with strict standards, the exploration of innovative approaches to fillet weld assessment and testing has actually ended up being important.

Advanced Non-Destructive Screening Approaches

Using advanced modern technologies, advanced non-destructive screening approaches play an essential duty in making sure the integrity and quality of fillet welds. These approaches, such as phased variety ultrasonic screening (PAUT) and magnetic particle testing (MPT), offer thorough insights right into the weld's inner framework without creating any kind of damages to the material. PAUT, as an example, uses numerous ultrasonic elements to inspect the weld from numerous angles, giving a detailed visualization of possible issues like absence of fusion or cracks.

Likewise, MPT works in detecting surface-breaking problems by applying an electromagnetic field and iron particles to the weld location. This method is specifically useful for recognizing suspensions that might compromise the weld's toughness. By employing these sophisticated non-destructive screening methods, weld assessors can properly analyze the top quality of fillet welds, making certain compliance with sector criteria and laws. The ability to discover imperfections early not just improves weld quality but additionally stops expensive rework or failures in structural honesty, underlining the significance of these cutting-edge testing strategies in welding inspections.

Robotics and Automation in Assessment

The combination of robotics and automation has actually revolutionized the evaluation procedure for fillet welds, improving performance and precision in high quality evaluation. Robotics supply exact control and repeatability in examining welds, guaranteeing reliable and regular outcomes. Automated systems can be set to follow specific assessment paths, ensuring thorough insurance coverage of welds and reducing the threat of human error.

Robot inspection systems outfitted with innovative sensors can discover and measure weld functions with high accuracy, offering comprehensive data for analysis. These systems can identify problems such as splits, absence of combination, and porosity, making it possible for punctual restorative activities to be taken. Furthermore, robotics and automation enable real-time information collection and analysis, supplying prompt feedback to drivers and helping with fast decision-making processes.

Moreover, the use of robotics and automation in fillet weld evaluation boosts total performance by decreasing assessment times and enhancing assessment throughput. By simplifying the examination process, manufacturers can guarantee weld high quality and compliance standards are fulfilled efficiently, eventually resulting in cost financial savings and enhanced product quality.

Using Artificial Knowledge for Analysis

Expert system plays an essential duty in boosting the effectiveness and precision of analysis in fillet weld examination processes. By harnessing the power of AI, inspectors can improve the analysis of weld high quality and compliance criteria, bring about more reputable and exact outcomes. AI algorithms can swiftly refine vast quantities of information from weld assessments, identifying defects or disparities that might be testing to understand the naked eye. This advanced technology allows real-time monitoring of weld high quality, permitting prompt rehabilitative actions to be taken if any kind of issues are detected.

Additionally, AI systems can find out from previous examination data, continually enhancing their capacity to identify prospective flaws and variances in fillet welds. This adaptive learning capability improves the total top quality control process, decreasing the probability of human error and ensuring reference that welds satisfy the required standards. By incorporating expert system right into fillet weld analysis, industries can accomplish higher levels of efficiency, consistency, and conformity in their examination practices.

Portable Equipment for On-Site Evaluation

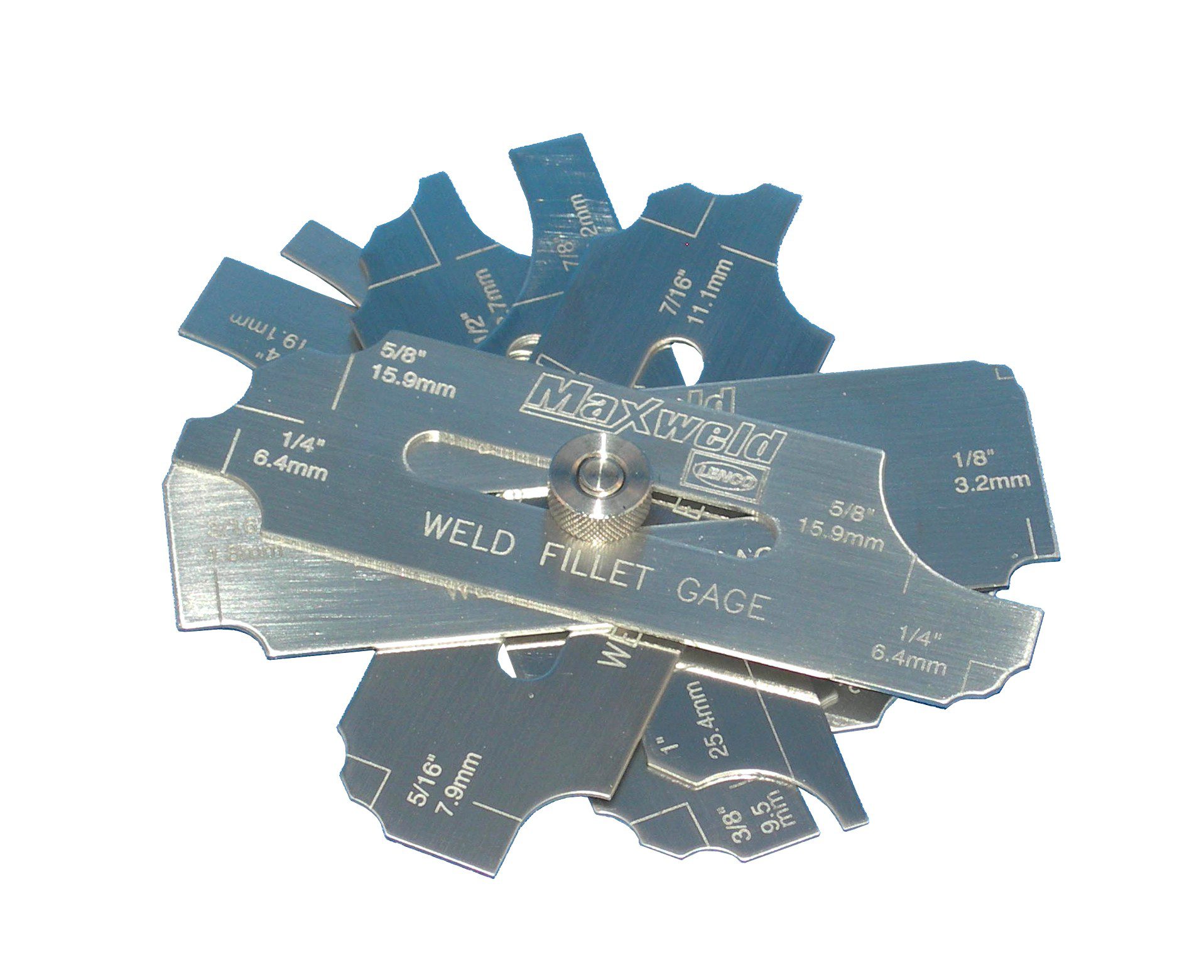

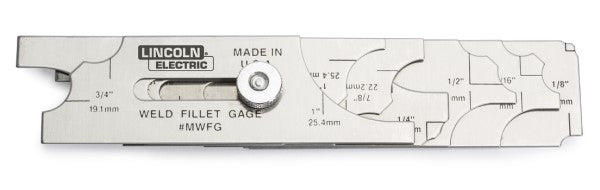

Enhancing field examination efficiency, the adoption of mobile tools changes on-site evaluation processes for fillet welds. These tools offer flexibility and benefit, allowing inspectors to carry out comprehensive exams in various locations, including remote or difficult settings. Mobile devices such as ultrasonic screening gadgets, magnetic particle assessment devices, and electronic radiography systems give real-time information and high-resolution imaging capabilities, enabling quick decision-making and prompt responses on weld quality.

One significant benefit of portable devices is their capacity to improve inspection procedures, lowering downtime and improving total productivity - Gauge Fillet Weld. Assessors can easily deliver these devices to various work websites, removing the need for transporting hefty machinery or components to off-site centers. Furthermore, the portability of these devices promotes cost-effectiveness by decreasing transport expenses and increasing examination timelines

In addition, the usage of portable tools for on-site evaluation promotes proactive top quality control steps, as assessors can immediately determine and deal with any potential welding issues or disparities. By integrating these cutting-edge innovations right into on-site inspection techniques, welding specialists can make certain compliance with sector criteria and enhance weld top quality, eventually leading to boosted structural honesty and safety and security in various welding applications.

Combination of Information Administration Solution

Having actually maximized on-site inspection procedures with the utilization of mobile devices, the next phase entails the seamless combination of information management systems to even more enhance efficiency and data analysis capacities in fillet weld examination and screening. By that site integrating information management systems into the evaluation procedure, organizations can streamline data collection, storage, and evaluation. This integration enables for real-time surveillance of weld high quality, immediate identification of defects, and prompt decision-making to rectify any type of issues that may develop during the inspection process.

Data monitoring systems play a critical role in systematizing examination information, helping with very easy accessibility for authorized employees, and ensuring data integrity and safety. Via the integration of these systems, assessors can produce comprehensive records, track historical data for fad evaluation, and boost general process performance. The combination of information administration systems makes it possible for smooth communication in between various stakeholders included in the evaluation procedure, promoting cooperation and enhancing general top quality control procedures. Inevitably, the assimilation of data management systems offers to elevate the standards of fillet weld assessment and screening, ensuring compliance with industry laws and enhancing weld high quality.

Conclusion

In conclusion, ingenious approaches to fillet weld examination and testing have substantially boosted weld high quality and compliance requirements. Advanced non-destructive testing methods, robotics, automation, man-made intelligence, portable tools, and information monitoring systems have transformed the means weld evaluations are carried out. By making use of these technologies, industries can make sure that welds meet the required high quality requirements and policies, eventually improving total performance and safety and security in welding procedures.

Having enhanced on-site examination procedures via the application of mobile devices, the next phase entails the seamless combination of data monitoring systems to better improve performance and information evaluation abilities in fillet weld assessment and testing. Ultimately, the assimilation More Info of information management systems serves to boost the requirements of fillet weld assessment and testing, making sure conformity with industry regulations and improving weld high quality.

Report this page